Concrete Inspection

Alt & Witzig provides concrete testing including Air Entrainment Content, Slump Testing, Cylinder Molding for Compressive Strength Testing and Yield Tests.

Alt & Witzig provides concrete testing including Air Entrainment Content, Slump Testing, Cylinder Molding for Compressive Strength Testing and Yield Tests.

Our experienced staff provides specialty testing services such as Floor Flatness evaluations for concrete floor slabs of larger industrial and school buildings.

Our specialty testing expertise also includes Swiss Hammer Testing, Windsor Probe, Petrographic Analysis, Hardened Air Content and Concrete Coring. Structural integrity is dependent upon proper concrete placement, and Alt & Witzig will provide thorough inspection support to assure the final product meets your project specifications.

Foundation Inspection

The best foundations are placed on solid ground. Our Foundation Inspections incorporate information gathered during the geotechnical phase and additional field-testing to ensure that a suitable bearing stratum is present to support your structure.

The best foundations are placed on solid ground. Our Foundation Inspections incorporate information gathered during the geotechnical phase and additional field-testing to ensure that a suitable bearing stratum is present to support your structure.

Alt & Witzig technicians will inspect your conventional foundation excavations for signs of soft or loose material, unsuitable soils, and irregularities. Our technicians are also trained to will inspect your extended footing excavations, drilled shafts, driven piles, and auger cast pile injection systems. These Foundation Inspections will help protect your project against the possibility of differential settlement after completion.

Laboratory Services

Alt & Witzig Engineering has materials testing laboratories located within each of our offices. Our in-house laboratories provide you with consistent, reliable test results in a timely manner.

Alt & Witzig Engineering has materials testing laboratories located within each of our offices. Our in-house laboratories provide you with consistent, reliable test results in a timely manner.

Our laboratories are managed by technical professionals under the supervision of professional engineers. Our Carmel, Indiana and West Chester, Ohio laboratories are regularly accredited by the American Association of State Highway and Transportation Officials (AASHTO), and are assesed by the Ohio and Indiana Departments of Transportation

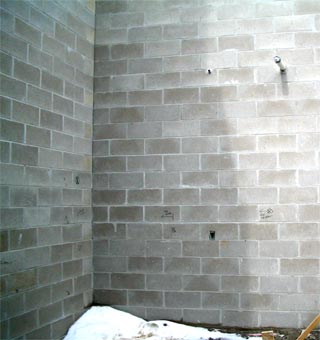

Masonry

Alt & Witzig Engineering, Inc. provides pre-placement, placement, and post-placement testing and inspection. These tests are performed in accordance with the American Concrete Institute (ACI), American Society for Testing and Materials (ASTM), and United Building Codes (UBC)/ International Conference of Building Officials (ICBO)/International Code Council (ICC) testing and inspection procedures.

Before placement we provide on-site inspection of:

- Masonry materials

- Reinforcing steel

- Embedded plates and anchor bolts

During placement we provide on-site field-testing to evaluate compliance with the project specifications. These tests include:

- Slump

- Air content

- Unit weight

- Observations of mortar, grout and air temperatures

- Casting of grout prisms and mortar cylinders/cubes for compressive strength

Once the masonry has been placed, we provide post-placement inspection and testing of:

- Curing and enclosure removal

- Wall lines and grades

- Compressive strength of CMU, grout prisms, and mortar cylinders/cubes

Soil Inspection

Structures supported by soil fill require careful monitoring of soil moisture and density during compaction. Alt & Witzig provides proctor tests, field moisture determination, and in-place soil density values to determine if your structure meets the project specifications

Structures supported by soil fill require careful monitoring of soil moisture and density during compaction. Alt & Witzig provides proctor tests, field moisture determination, and in-place soil density values to determine if your structure meets the project specifications

On-site soil inspections and recommendations from our engineering staff provide you with the best approach to complete your earthmoving phase.

Alt & Witzig utilizes sophisticated equipment to perform timely in-field testing. Our regularly calibrated equipment allows accurate testing of fill lifts up to twelve inches thick. Our materials license requires that the Nuclear Regulatory Committee regularly inspect our gauges and facilities. We insist on using our superior equipment to provide you with the most accurate and timely results.